Industrial Waste Water Treatment in UAE

- Industrial Waste Water Treatment in Dubai

Industrial Waste Water Treatment in UAE

Rethinking Water (RTW) provides structured and results-focused solutions for wastewater issues across industrial operations in the United Arab Emirates. Our team works with regulated technologies and proven designs that meet sector demands while supporting environmental responsibility.

We specialize in engineered treatment processes that align with national regulations and broader environmental goals. The purpose is not only to manage discharge but also to recover resources and maintain system efficiency. RTW is committed to improving every stage of the industrial wastewater cycle across diverse industries and locations.

Treatment Methods and Operational Approaches

Each treatment stage must be engineered to fit local discharge requirements, site limitations, and the chemical load involved. Before implementation, RTW conducts site-specific feasibility assessments. These assessments guide the selection of proven operational methods. The points below explain the structured systems we apply across all treatment phases.

Primary Solid Removal

The system begins with removing floating solids and grit. It includes screening and sedimentation as part of the primary treatment of wastewater sewage, which prepares the water for downstream treatment phases.

Secondary Biological Processing

Organic pollutants are broken down using natural metabolic activity. This stage supports the wastewater treatment objective of reducing chemical loads and controlling oxygen demand.

Advanced Filtration Systems

Membranes and sand filters handle the final separation of small particles. These wastewater treatment working models are adjusted based on site-specific pressure, flow rate, and water quality metrics.

Neutralization and Chemical Balancing

Chemical dosing is used for pH control and coagulation. This is a critical method used in the treatment of wastewater that removes toxic materials before final polishing.

Sludge Management Protocols

Sludge output is dewatered using belt presses and treated for safe disposal or repurposing. No stage is left unmanaged, and every outcome is accounted for with supporting documentation.

Primary Stages of Preliminary Wastewater Processing

Primary treatment forms the foundation of all modern wastewater purification systems. It removes suspended solids and floatable materials early in the cycle, reducing strain on downstream equipment. This stage is crucial for optimizing chemical use, improving system efficiency, and ensuring compliance with operational and environmental discharge standards.

Initial Screening Procedures

Wastewater enters treatment facilities containing a range of solid materials. To avoid mechanical failures later in the system, initial filtration begins with coarse, fine, and micro screens. These intercept plastics, rags, and fibrous debris. Most facilities rely on automated cleaning to ensure uninterrupted performance.

Grit Isolation and Extraction

Following screening, the wastewater moves through grit chambers designed to remove heavier inorganic particles such as sand and crushed solids. Horizontal-flow, aerated, or vortex designs are selected based on flow characteristics. Removing grit at this point prevents abrasion and extends the life of mechanical components downstream.

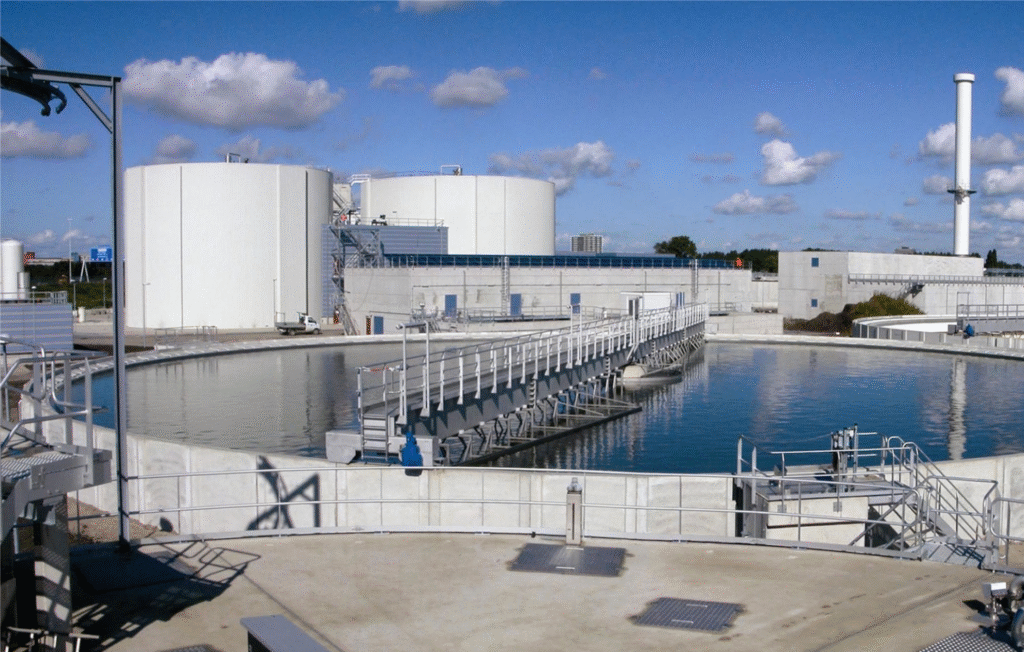

Gravity-Based Settling Mechanism

Once screened and de-gritted, water enters large clarifiers. These tanks hold water long enough for solids to settle and form primary sludge. Simultaneously, lighter substances like fats and oils float to the surface and are skimmed. Clarifiers may be circular with rotating arms or rectangular with longitudinal scrapers.

Use of Coagulants and Flocculants

In some applications, sedimentation efficiency is improved by introducing chemicals. Coagulants neutralize particle charges, while flocculants bond the particles together into larger masses. These combined materials then settle more easily. This chemically enhanced primary treatment can significantly raise removal rates of solids and lower biochemical oxygen demand (BOD).

Industrial Waste Water Treatment across the UAE

Treatment demands vary based on industry size, location, and the contaminants present in the effluent. RTW’s systems are active across different cities in the country and reflect real working needs. These sites support a wide range of industrial processes and maintain service continuity.

Abu Dhabi: Centralized planning and plant-wide monitoring for long-term discharge stability.

Dubai: Compact industrial wastewater treatment plant in UAE locations focused on high-footfall areas and export-driven industries.

Sharjah: Energy-efficient solutions for moderate-scale factories with varying seasonal loads.

Ajman: Flexible wastewater treatment services in UAE covering food, chemicals, and small manufacturing zones.

Fujairah: Long-range pipeline integration with remote facility link-ups for continuous treatment coverage.

Speak with a Team That Knows UAE Compliance

RTW is one of the few wastewater treatment solution providing companies in the UAE with full-scope planning and implementation capabilities. We handle the design, material selection, and process integration with strict attention to performance standards. Contact us today to discuss your site’s wastewater targets and start with a system that delivers stable, safe, and verified outcomes.

FAQs

Frequently Asked Questions

Industries like oil, food, textiles, and chemicals must follow UAE discharge laws and treat water properly.

Yes, RTW is registered and operates across approved zones with licensed engineers and certified staff.

The first step is a feasibility and load study that helps define the required components and build size.

Installations may take weeks or months, depending on flow rate, chemical load, and site readiness.

Yes. Our team provides upgrades to meet newer laws or to improve energy and recovery performance.