Advance Oxidation Process

- Advance Oxidation Process

Advanced Oxidation Solutions for Industrial Effluent

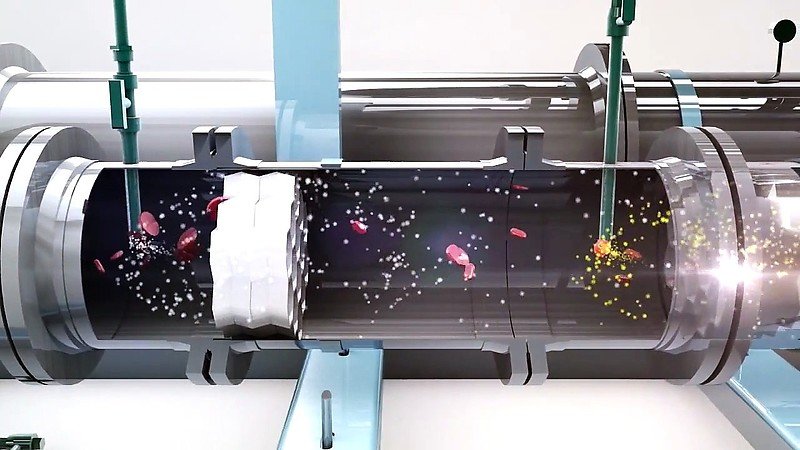

Modern industries across the Middle East face increasing pressure to manage wastewater containing persistent pollutants. Advanced oxidation process technology offers a reliable pathway to break down resistant compounds that traditional methods cannot handle. These systems generate hydroxyl radicals and other reactive agents capable of degrading complex organics. RTW delivers a specialized advanced oxidation process for wastewater treatment systems that combine efficiency with environmental responsibility. Our capabilities include Electrocoagulation (EC) and Electro-Oxidation (EO). Both are widely recognized for their operational stability and cost-effectiveness with adaptability across diverse sectors.

Electrocoagulation (EC)

Electrocoagulation is a proven method for removing suspended solids and emulsified oils as well as metals from industrial effluent

Operational Method:

Direct current is introduced into wastewater through metallic electrodes.

The electrodes release ions that destabilize charged contaminants.

Pollutants bind into larger flocs that are removed via sedimentation or filtration.

Advantages of EC

Chemical Independence

Reduces reliance on external coagulants.

Industrial Flexibility

Applicable across textiles, petrochemicals, food, and beverage sectors.

Energy Conscious

Achieves high treatment outcomes with low power use.

Electro-Oxidation (EO) Systems

Electro-Oxidation is an electrochemical method that generates powerful oxidants, including hydroxyl radicals, directly within the water matrix.

Operational Method:

Current applied to electrodes produces oxidizing species.

These species degrade complex molecules or mineralize them into water and carbon dioxide.

Advantages of EO

High Contaminant Reduction

Treats pesticides, dyes, pharmaceuticals, and other persistent pollutants.

Low Residual Sludge

Limits secondary waste production.

Integrated Disinfection

Neutralizes bacteria, viruses, and microorganisms.

Combined EC and EO Systems

EC and EO deliver a comprehensive approach when applied together. EC removes solids and heavy metals, while EO addresses dissolved organic matter and pathogens. This combined framework improves the advanced oxidation process. It results in effluent that consistently meets strict discharge standards in the Middle East.

Industrial Applications of AOPs

Treatment of textile industry wastewater, including dye residues.

Petrochemical and refinery effluents.

Food and beverage processing discharges.

Chemical and pharmaceutical manufacturing effluents.

RTW stands among recognized advanced oxidation process vendors that offer end-to-end project delivery. Each solution is engineered to ensure compliance and operational savings with measurable environmental improvement.