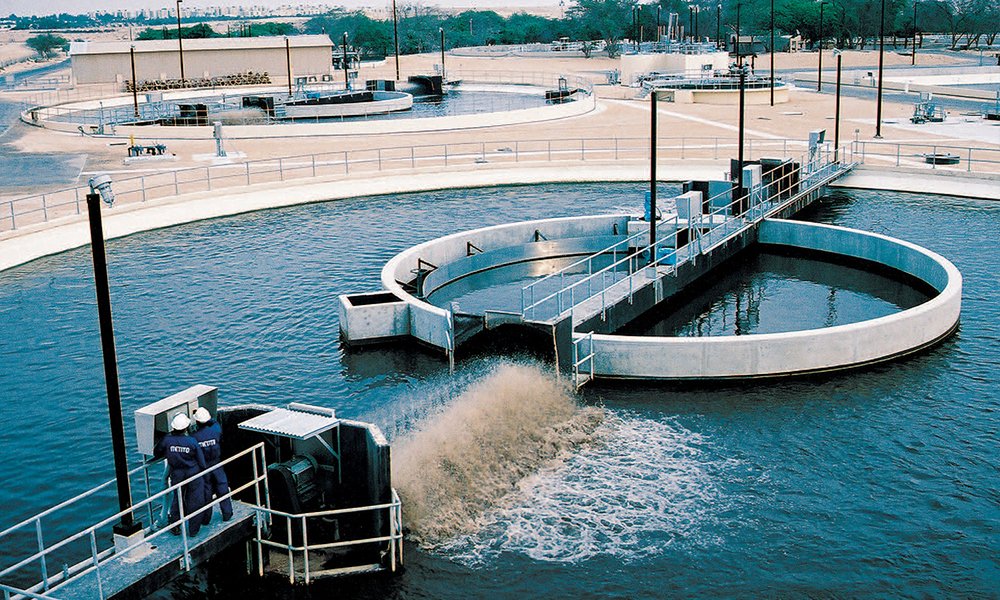

Industrial Waste Water Treatment in Qatar

- Industrial Waste Water Treatment in Qatar

Industrial Waste Water Treatment in Qatar

Waste water treatment companies in Qatar play a critical role in this transition by offering treatment systems designed for high performance, minimal waste, and long-term water reuse. At RTW, we develop and deliver professional, engineered systems to handle the complex wastewater challenges found in industrial zones across the country.

Qatar’s rapid industrial growth has increased the demand for reliable water reuse systems. With environmental regulations becoming stricter, industries now require solutions that are both compliant and sustainable. That is why RTW focuses on providing businesses with the right solutions to meet their needs.

Advanced Solutions for Industrial Water Challenges

RTW provides tailored treatment strategies that are built around industry demands. We focus on performance, efficiency, and compliance, ensuring our clients get proven results across a wide range of applications.

Chemical Wastewater Treatment

Industrial zones producing high-strength chemical wastewater require robust technology. We design systems that neutralize hazardous compounds, treat pH imbalances, and remove dissolved and suspended solids, while supporting full regulatory compliance.

Oil and Grease Separation

Oil-rich effluents from manufacturing and refinery sectors need specialized treatment. Our skimmers, DAF units, and separators handle free and emulsified oil efficiently, reducing environmental impact and meeting discharge limits.

Zero Liquid Discharge (ZLD) Systems

RTW integrates membrane filtration, evaporation, and crystallization to achieve ZLD. These systems recover water and valuable resources while leaving behind minimal solid residue. They’re ideal for water-scarce regions like Qatar.

Biological Wastewater Processing

For food and beverage or pharmaceutical sectors, we deploy aerobic and anaerobic processes to break down organic matter. These methods are energy-efficient and comply with all local discharge regulations.

Core Mechanics of Initial Wastewater Treatment

The primary treatment phase focuses on separating non-dissolved pollutants from incoming wastewater. This stage creates the operational stability necessary for efficient downstream treatment. Through mechanical and chemical means, solids, oils, and grit are removed, helping facilities reduce biological loads and maintain long-term functionality of all subsequent systems.

Stage One: Screen-Based Filtration

Initial separation begins with screening. These mechanical barriers catch unwanted solids before they can enter delicate treatment components. Coarse screens handle bulky waste. Fine and micro screens capture smaller fragments. These filters often include automated rakes or brushes to keep channels clear during continuous flow conditions.

Stage Two: Grit Separation

The next step addresses non-organic debris. Particles like gravel and sand, although small, can wear down pipes and pumps if not properly isolated. Grit chambers—horizontal, aerated, or vortex—slow the flow of water just enough to allow these particles to sink and collect at the base.

Stage Three: Gravity Clarification

With large and heavy solids removed, wastewater is directed into clarifiers. These tanks provide the time and space for suspended solids to settle as sludge. Oils, grease, and lighter materials rise to the top. Both layers are continuously removed by rotating or linear skimming mechanisms.

Optional Step: Chemical Assistance

In some cases, sedimentation is enhanced by introducing coagulants and flocculants. These substances help small particles aggregate into larger clusters, accelerating settling. This chemically supported approach can increase the removal rates of suspended solids and reduce the biochemical oxygen demand passed on to later stages.

Industrial Waste Water Treatment Across Qatar

Our systems are in operation across major industrial hubs in Qatar. Each location has its own set of challenges, and we tailor every project accordingly.

Doha: Engineered systems for mixed industrial zones with high organic and chemical loads.

Al Wakrah: Support for fishery, food processing, and textile-related effluents.

Ras Laffan: Advanced ZLD and chemical treatment for petrochemical complexes.

Mesaieed: Integrated plants designed for chemical, fertilizer, and refining industries.

Umm Said: Sludge handling and water reuse solutions for manufacturing clusters.

How RTW Ensures Long-Term Performance

Our treatment systems are designed with long-term reliability in mind. From early-stage design to post-installation monitoring, every step is managed by experienced engineers.

Design Built on Real-World Data

We analyze influential characteristics before developing a system. This ensures that every solution meets site-specific conditions with minimal adjustments post-installation.

Modular and Scalable Units

Whether a client needs a compact treatment system or a full-scale industrial wastewater treatment plant in Qatar, our modular designs allow for easy expansion and upgrades.

Automation and Remote Monitoring

All systems are equipped with sensors and control units. This minimizes manual work, detects faults early, and keeps plant performance stable year-round.

Sludge Management and Dewatering

Solid waste from treatment is managed through presses, dryers, and filters. This reduces hauling costs and enables the possible reuse of sludge in the cement or agriculture sectors.

Chemical Optimization and Dosing Systems

Our dosing systems are tailored to reduce chemical use and maximize treatment impact, lowering operating costs while maintaining compliance with national regulations.

Serving the Middle East Industrial Sector

As one of the leading wastewater treatment solution providing companies in Qatar, RTW extends its expertise across the wider region. From Saudi Arabia to Oman and the UAE, our systems help industries reduce waste, reuse water, and meet strict environmental policies. As wastewater treatment in the Middle East becomes a national priority, RTW is positioned to lead with proven technology and reliable partnerships.

RTW helps industries meet environmental targets with engineered solutions that perform on-site, over time, and under regulation. Every system we build reflects deep technical knowledge and respect for local needs. Partner with us to strengthen your water management strategy and prepare for a more sustainable industrial future.

Why RTW Leads Among Waste Water Treatment Companies in Qatar

RTW applies tested processes, clear engineering models, and precise execution in every treatment project. Our consistent focus remains on addressing each industry’s unique wastewater issue with reliable, practical methods. The following areas reflect how RTW continues to lead among wastewater treatment companies in Qatar by solving critical treatment problems.

Industry-Specific Expertise

Our engineers understand the demands of heavy industries, enabling custom system design that meets both operational and regulatory needs.

Reliable Performance Over Time

We build treatment plants with corrosion-resistant materials, durable components, and long-term automation strategies.

Client-Centric Project Management

Each client works with a dedicated team, from consultation to commissioning, ensuring clarity, timeliness, and technical consistency throughout.

Regional Focus and Compliance

We align every solution with local environmental regulations and climate conditions, setting us apart from general wastewater treatment companies operating without localized insights.

FAQs

Frequently Asked Questions

We serve oil & gas, chemical, food processing, textiles, mining, and electronics industries with tailored wastewater treatment systems.

Depending on size and complexity, installation can take 3–6 months, including design, delivery, and commissioning.

Not always. ZLD is often required in water-scarce or highly regulated zones. We assess its necessity during consultation.

Yes. Our systems recover treated water for reuse in irrigation, cooling, or internal processes where allowed.

Yes. Our modular and automated systems are built to handle variable flow rates and influent loads year-round.